- CREATE A BLOCK IN LIBRECAD FULL

- CREATE A BLOCK IN LIBRECAD SOFTWARE

- CREATE A BLOCK IN LIBRECAD SERIES

It is easy to rescale things in LibreCAD. I decided to divide the design into twoĭrawings but even then it was going to be a problem fitting it all on to the laser bed so I decided to rescale the design so that the solar kiln could beĬut on two seperate sheets. The Epilog Mini24 has a cutout bed of 600x300mm so it became obvious that I couldn't cut my design in one go.

CREATE A BLOCK IN LIBRECAD FULL

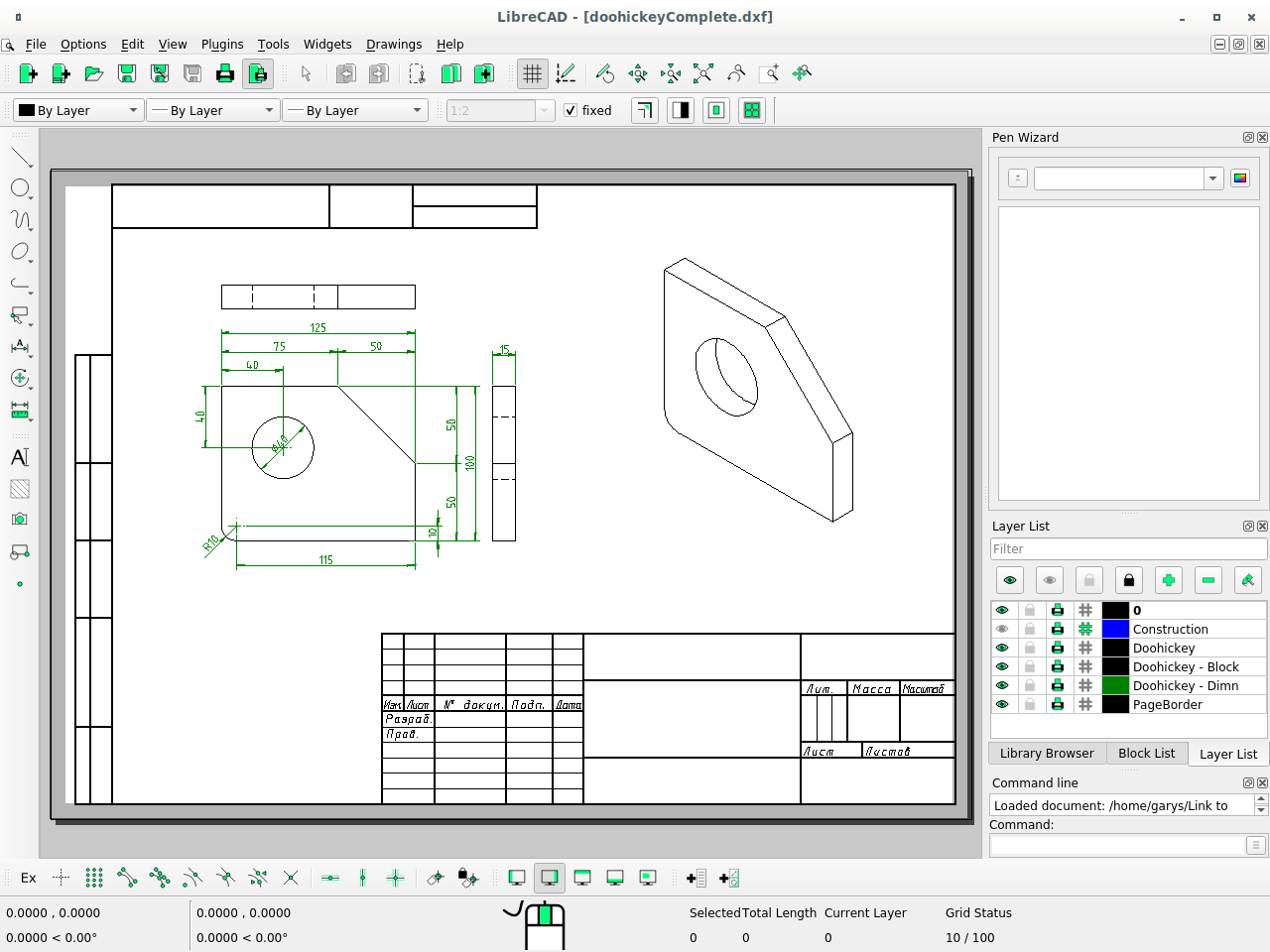

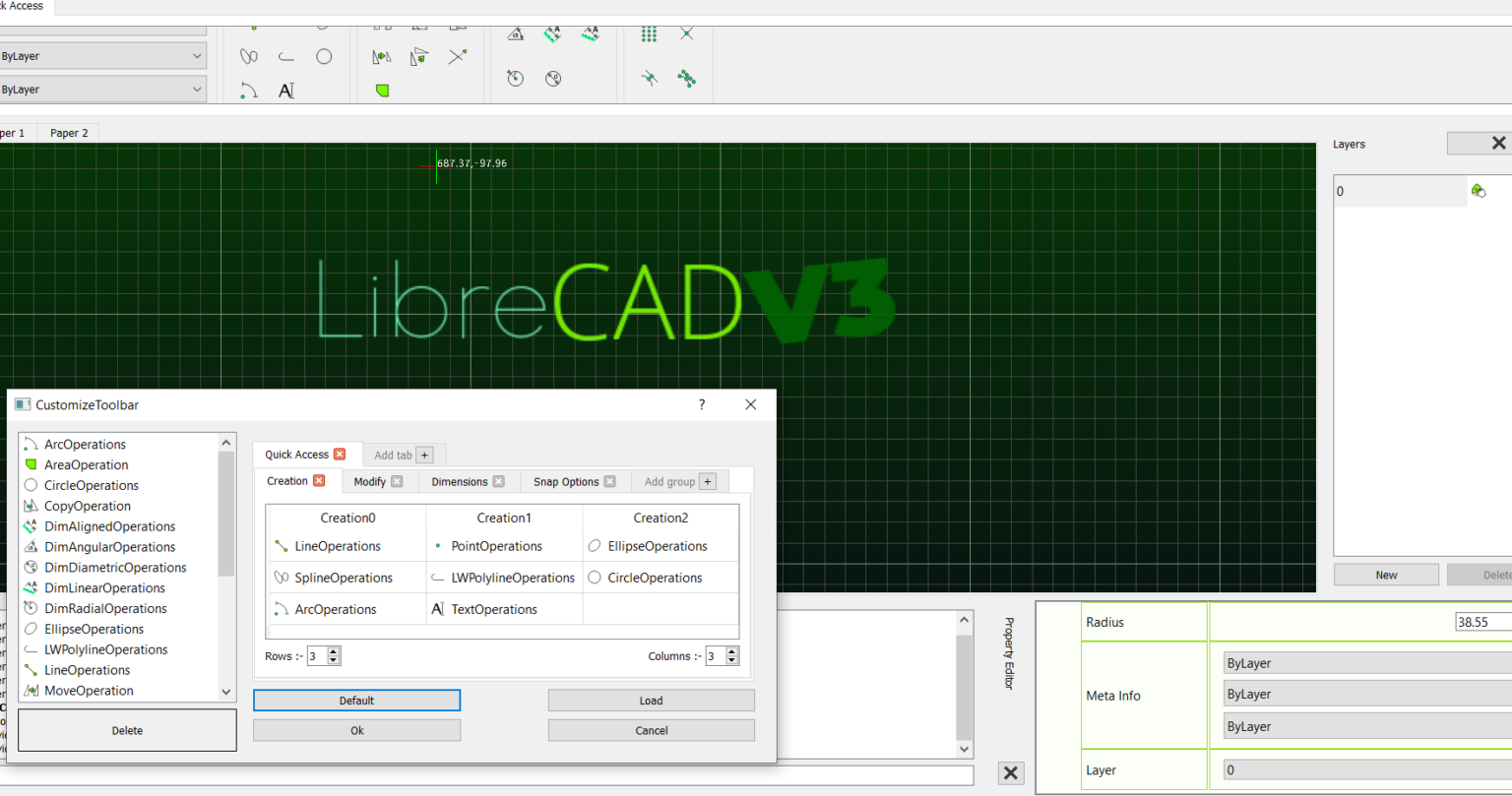

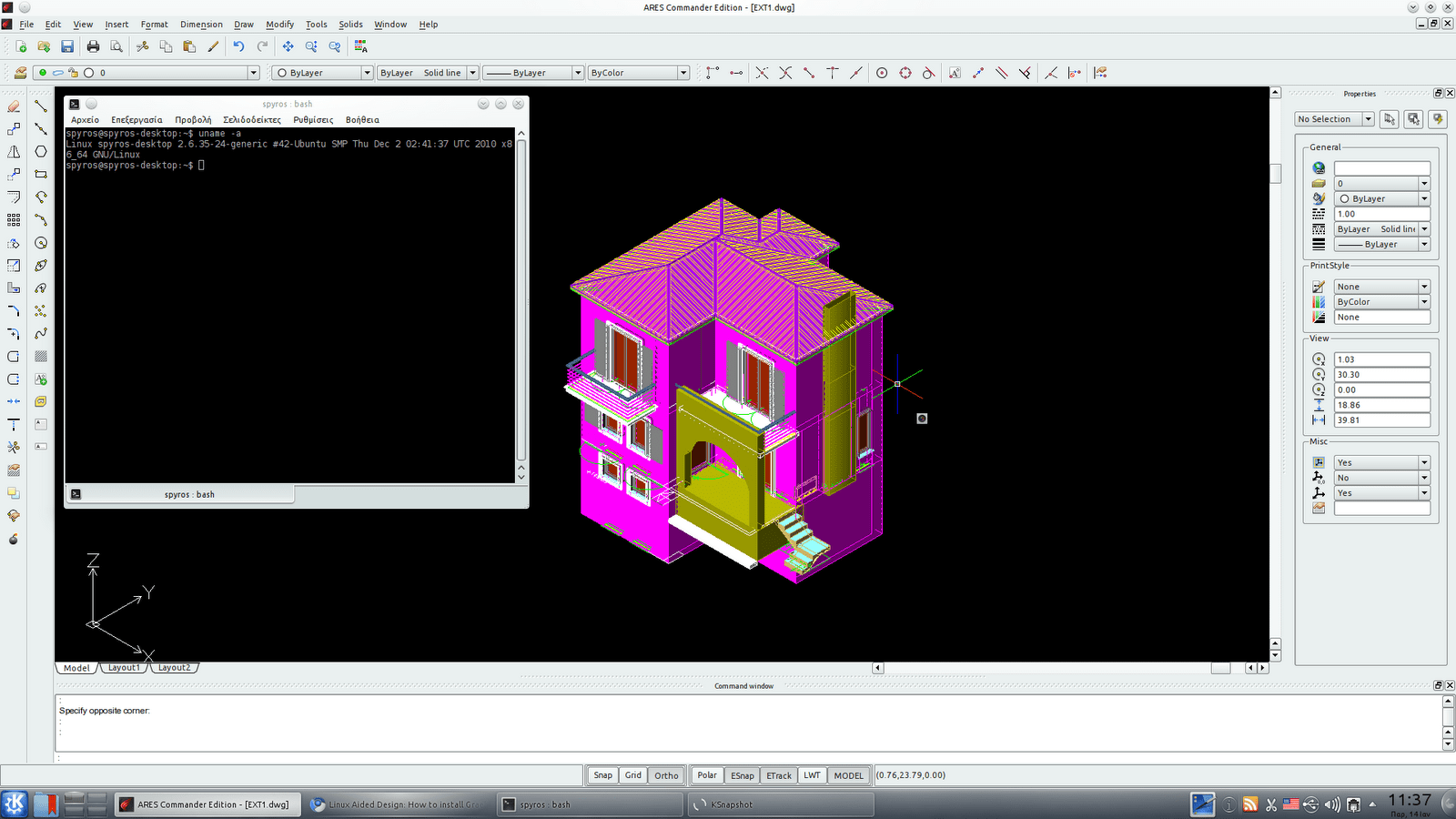

The LibreCAD solar kiln design is shown below while the full design can be downloaded from solarkiln.dxf When later I had a problem fitting the design to a size suitable for the laser cutter I was able to use the scale parameter Modified to meet new design scenarios such as a change in the thickness of build material or resizing part of the design which automatically causes any Object to be drawn containing geometries that are related to each other via rules created by the designer or CAD tool.

CREATE A BLOCK IN LIBRECAD SOFTWARE

We had been told to use CAD software that was parametric which allows a design With the kerf test using the 30mm square the cut piece was 0.74mm short, ie. The first image below shows the cutout template while the second image indicates that for the 3mm cardboard a 2.7mm slot produced the best fit.Ī 30mm square was also cut out and this was measured to see how the dimensions had reduced due to kerf. Nim generated an Inkscape file combslottest3mm.pdf which would be used to laser cut the test material and check for slot widthĪnd kerf.

CREATE A BLOCK IN LIBRECAD SERIES

To do this a series of joints are cutout on a test sample of material, therby allowing the kerf to be measured and joint widths and heights Latter requirement the cutout waste or kerf produced by the laser cutter needs to be known and fed back into the CAD to allow accurate joints to be drawn and then For this to happen means accurately specifying the joints in the CAD and accurately cutting the design out. In both cases the materials had to be cut to produce joints Along with my fellow student, Nim, we had two types of materials to cut:ģmm plywood for Nim's assignment and nominally 3mm cardboard which would be used for my model.

The laser cutter used was an Epilog Mini 24 with a 40 watt tube.

The model will be of a solar kiln and the point of this assignment is to see if a press fit construction kit of the model can be made.

0 kommentar(er)

0 kommentar(er)